9W

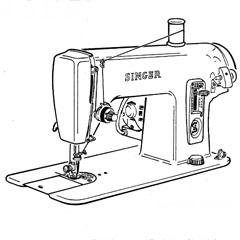

A Wheeler & Wilson D9 produced by Singer at Bridgeport after 1905, notable for its square section pillar, later modified for interchangeability with Singer fittings and produced as the 9W7 until 1913.

The following photos are provided as an aid in identifying common vintage Singer sewing machine models.

The models below are old, antique models from 1865-1970.

A Wheeler & Wilson D9 produced by Singer at Bridgeport after 1905, notable for its square section pillar, later modified for interchangeability with Singer fittings and produced as the 9W7 until 1913.

Introduced in 1865, this mass produced sewing machine remained in production for almost 40 years and features a transverse boat shaped shuttle and an early fiddle base bed later changed to a rectangular shape.

Introduced in 1870, the semi-industrial 13K is a treadle mounted Singer machine with a New Family based mechanism, a longer arm, a 15.5 by 7.375 inch bed and an extra sliding inspection plate.

This variant uses a type PG potted motor mounted at the back of the main pillar and drives the machine directly through internal gearing.

A class 15 Singer variant for domestic and light industrial use produced in many versions including semi industrial types with heavier faceplates and later models fitted with reversible feed and dropping feed dogs.

A Class 15 variant distinguished by a more angular body shape and issued with subversions numbered 125 and 126.

A domestic variant of Singer's chain stitch Model 24, configured for treadle operation with automatic tension and producing a decorative single thread chain stitch commonly used for millinery and applied trim.

Smaller three quarter size vibrating shuttle domestic machine, produced in Scotland as the 28K, typically a portable hand crank model whose later versions gained a higher bobbin winder, shuttle ejector and automatic tension release.

A British made chain stitch miniature sewing machine produced at Kilbowie in 1912–13 in a limited run of about 15,500, cast iron built, weighing 5 kg and using short 24x1 needles.

Produced only at the Kilbowie factory from 1900 to 1913, this transverse shuttle Singer used a hybrid enclosed shuttle and a mechanism derived from the 13K and featured unique bed dimensions that prevent case interchange.

Full size heavy duty domestic machine weighing about 30 pounds, produced 1907 to 1939 in Britain and until 1956 in the USA, notable for its horizontal rotary hook with drop in bobbins but lacking reverse feed.

A 3/4 size domestic electric budget machine produced during 1963 to 1965, the 98K is free standing with a hammered gold finish, cloth cover, pressed metal foot pedal and no work light.

A 3/4 size portable domestic machine sharing the class 66 mechanism, produced until about 1958 and notable as the first portable electric model after a motor option was offered in 1921.

Electric portable with a solid flywheel, reverse feed for backtacking, and graduated tension control, using standard low shank screw on feet and 15x1 needles.

A basic small lightweight plastic sewing machine intended for occasional light use, inexpensive and lacking sophisticated controls, not suitable for heavy work and unlikely to be regarded as repairable.

Based on the 9W7 with a rotary hook, it incorporates class 15 peripheral features and uses industrial 20U style bobbins and was commonly finished with the 'Gold Wings' decal.

A modern cheaply made small basic lightweight plastic Singer, designed for occasional light use and beginners rather than heavy or professional work, with simple controls and limited prospects for repair.

A 3/4 scale domestic vibrating shuttle sewing machine and minor development of Singer 27K and 28K, with the bobbin winder mounted higher so the rubber tyre runs on the belt, discontinued in 1962.

A flatbed horizontal oscillating hook sewing machine produced 1974 to 1977 with a metal body, plastic top arm cover and an integral motor built into the main column, paired with tubular 161.

A flatbed horizontal oscillating hook home sewing machine produced from 1974 to 1977, with metal body, plastic top arm cover and integral column motor and added selectors for stretch stitch and blind stitch.

A basic member of the 1970s Capri family, this horizontal oscillating hook flatbed machine features a metal body with a plastic top arm cover and an integral motor built into the main column.

Made at Kilbowie in Scotland from 1958 to mid 1963, this three quarter full size portable is a cosmetically repackaged electric version of the 99K that reused the 99K's mechanisms and many parts.

A cast iron straight stitch domestic machine with a vertical oscillating hook, it offers reverse stitching and a drop feed for free motion work and was produced in multiple Singer factories.

It was produced between 1959 and 1961 as a budget version of the class 99 machines and was supplied in a simple moulded plastic base without a cover.

This model was made in Queretaro, Mexico.

A heavy, sturdy vertical oscillating hook sewing machine produced in Monza, Italy during the 1960s, with User's Manual Form 460M and Service Manual Form 486M.

A member of Singer's top of the range 201 series built in the UK and produced from 1935 to 1962 this full size straight stitch domestic machine was offered as treadle hand crank or motorised variants.

Aluminium bodied mid 1950s update with a lighter 24 lb portable case, solid balance wheel and BAK4 belt drive motor, retaining the 201's top range straight stitch mechanics and produced circa 1954 to 1962.

Made at Singer's Kilbowie factory, this class 206 domestic zigzag machine was produced between 1936 and 1953 and requires special 206x13 short point needles while using large vertical 55623 bobbins.

A cast iron straight stitch machine with a vertical oscillating hook, produced as one of the first Singer models at the Karlsruhe factory after Singer took over production in 1954 and carrying PA plus six-digit serial numbers.

One of the first machines produced at the Karlsruhe factory after 1954 with PA plus six digit serial numbers, it features a front facing vertical oscillating hook and a zigzag sewing facility.

An early mid 1950s Karlsruhe factory production, this Haid und Neu design was adapted from the 28/128 pattern and carries serial numbers beginning PA or PB followed by six digits.

A cast iron zigzag machine made at Singer's Utsunomiya factory in Japan during the 1960s, it accepts treadle hand crank or external motor drives and includes six pattern cams plus a presser foot pressure dial.

Manufactured in Penrith, Australia, this variant was produced at Singer's Penrith factory while related 227M and 228M variants were manufactured in Monza, Italy.

A domestic sewing machine built in Kilbowie and virtually identical to the 285K but featuring a permanently wired foot pedal speed controller instead of the conventional detachable three pin plug and socket.

Built in St. John's Canada from 1963 to 1965, this redesign of the earlier 185 introduced an oscillating rack and pinion lower hook drive that made it noisier and prone to vibration.

A 3/4 size domestic electric budget machine produced 1963 to 1965, free standing with an external Singer CBK motor and V belt, grey hammered finish and a clip on rexine covered plywood case.

The 288C is a zigzag domestic sewing machine made in Campinas, Brazil in the 1970s and early 1980s with an aluminium body, external motor, horizontal oscillating Apollo hook, drop in plastic bobbin and 11 pattern cams.

Built at Bonnieres, France about 1963, this straight stitch zigzag machine uses a vertical oscillating hook and aluminium body with an external motor and permits dropping the feed dogs for free motion while threading right to left.

A Taiwanese made late 1970s model available with an external motor or mounted in a treadle table, featuring a pivoting left front plate that reveals a Type A pattern cam.

A first slant shank Singer sewing machine built at the Anderson South Carolina factory, offered in black or beige and manufactured in the mid 1950s (serial ranges NA186001 to NA500000 and NB000001 to NB200000).

Produced at Kilbowie between 1954 and 1961, this cast aluminium model features a built in zigzag, twin spool pins for twin needle decorative stitching, full reverse feed and a disconnectable feed for free motion work.

A heavy cast iron 1960s zigzag domestic machine made at Karlsruhe, weighing over 16kg, with built-in legs, a front-facing vertical oscillating hook, replaceable pattern cams and standard needles and bobbins.

A full size zigzag domestic sewing machine produced 1956 to 1961, developed from the Model 306, featuring piano key operated built in stitch patterns, external Type A pattern cams and industrial 20U bobbins with 206x13 needles.

A free arm zigzag sewing machine produced from 1958 to 1961, it features a two section removable wooden bed with spring latches and uses industrial 20U bobbins and 206x13 needles.

A modern small basic lightweight plastic domestic sewing machine intended for occasional light use rather than heavy or serious work, inexpensive and not regarded as repairable.

1960s aluminium bodied zigzag sewing machine featuring a single fixed pattern cam for the zigzag stitch, an internal belt driven motor with all steel hook drive and low shank feet.

Australian-built variant of Singer's 328 'Style-O-Matic' zigzag machine made at Penrith, offered in tan or grey and featuring interchangeable Type A disc cams for a wide range of decorative stitches.

Made in Bonnieres, France in the 1970s, this portable model features an aluminium chassis clad in removable plastic panels, a slide on storage cover with carrying handle, and an internal motor controller accessed via a hinged flap beneath the case.

A portable 1970s sewing machine made in France with an aluminium chassis encased in removable plastic panels, this variant adds a zigzag stitch for stretch fabrics and stores its motor controller inside the slide on case moulding.

This European-built variant was assembled at Singer's Karlsruhe factory in Germany.

German made domestic machine produced in small numbers in 1964 and 1965, built on the class 201 design with a direct gear driven rotating hook, all metal gears, slant shank zigzag and eight built in patterns.

An aluminium bodied zigzag sewing machine with a plastic front plate mounting controls, a horizontal rotating hook, an internal SN open frame motor in the main pillar, an underside top arm lamp and built 1968 to 1978.

An aluminium bodied zigzag machine with a plastic front plate housing its controls, a horizontal rotating hook, an internal type SN open frame motor in the main pillar, underside lamp and built 1968 to 1978.

Made in Germany, this zigzag domestic machine uses a direct gear driven rotating hook with all metal gears, offers a removable bed to form a free arm, eight built in zigzag patterns and optional pattern cams.

Part of the 400 series family, this aluminium bodied zigzag machine has a plastic frontplate housing the controls, uses a horizontal rotating hook with an internal SN motor and includes a lamp under the top arm, made 1968 to 1978.

An aluminium bodied zigzag machine from Singer's 400 series featuring a plastic front plate with mounted controls, a horizontal rotating hook and an internal SN open frame motor produced between 1968 and 1978.

A 400 series aluminium bodied zigzag sewing machine with a plastic front plate housing controls, a horizontal rotating hook and an internal SN open frame motor in the pillar produced between 1968 and 1978.

An aluminium bodied zigzag home sewing machine from Singer's 400 series with a plastic front plate mounting controls, a horizontal rotating hook and internal SN open frame motor built into the pillar, produced from 1968 to 1978.

A straight stitch only variant of the Singer 400 series produced from 1968 to 1978, it served as an exception within the series otherwise characterised by aluminium bodied zigzag machines with control levers mounted in a plastic frontplate.

Introduced in 1969 as a sleeker domestic model, it combined a metal body with plastic trim, an internal motor with toothed belt drive and built in zigzag blind stitching and twin needle functions, plus a quick release needle plate.

An aluminium bodied zigzag sewing machine with a plastic frontplate, horizontal rotating hook and internal SN open frame motor built 1968 to 1978, modified in 1969 to add quick change throat and feed cover plates.

An aluminium bodied zigzag domestic sewing machine with a plastic front plate housing controls, horizontal rotating hook and internal SN open frame motor, with a lamp incorporated under the top arm and produced 1968 to 1978.

A 1976 aluminium bodied 500 series domestic machine featuring a horizontal rotating hook and internal type SN open frame motor provided as a flatbed model with ZZ three stitch capability.

Manufactured 1961 to 1963 at Singer's Anderson South Carolina factory as one of the last slant shank models produced there before the factory ceased making sewing machines.

Produced 1974 to 1976, this aluminium bodied 500 series machine uses a horizontal rotating hook and internal SN open frame motor and is the flatbed version of the tubular bed 527 model.

A 1973 to 1975 aluminium bodied 500 series domestic machine with a horizontal rotating hook and internal SN open frame motor, providing zigzag stitching with five stitch patterns in a flatbed configuration related to the 533.

An aluminium bodied 500 series domestic sewing machine made 1973 to 1975, featuring a horizontal rotating hook with an internal SN open frame motor, seven stitch selections and a four step buttonholer as the flatbed of model 534.

An aluminium bodied 500 series domestic sewing machine built 1973 to 1980 featuring a horizontal rotating hook and an internal type SN open frame motor housed in the machine pillar.

A 1975 aluminium bodied 500 series domestic ZZ machine with a four step buttonholer, flatbed configuration, horizontal rotating hook and internal SN open frame motor.

An aluminium bodied 500 series domestic machine built 1974 to 1977 with ZZ and blind stitch functions and a tubular bed based on the 502.

A 1975 to 1976 aluminium bodied 500 series domestic zigzag machine with a tubular bed based on the 507, employing a horizontal rotating hook and an internal type SN open frame motor within the main pillar.

A zigzag domestic machine produced 1977 to 1980 with a tubular bed, aluminium bodied and using a horizontal rotating hook with an internal type SN open frame motor in the main pillar.

Dating from c.1975, the machine features snap on presser feet, a chainstitch option, 'magic bobbins' rewound in place, and a clear slide plate window to monitor remaining thread.

Manufactured in Campinas, Brazil in the 1970s and early 1980s, this zigzag sewing machine is similar to the 288C and features 19 interchangeable pattern cams.

An aluminium body zigzag sewing machine built in Karlsruhe around 1979, featuring six built in stitch patterns and expandable decorative options via type B pattern cams and type C Flexi-Stitch cams.

Produced by Singer from 1941 to 1953, these variants used chemically blacked or black crinkle paint finishes on components, were relatively rare, and applied to limited runs of models including 66, 99k, 128 and 221.

A series of Singer domestic machines produced between 1851 and 1885, beginning with the wooden case Model No. 1 and evolving to iron stand and oscillating shuttle designs that increased sewing speed and workspace.

A compact 12V constant speed mending machine made in France from 1982, built on an aluminium chassis with plastic covers, plastic sliding shuttle and long plastic bobbins, fixed presser foot and nonadjustable tension.

A domestic vibrating shuttle sewing machine with a fiddle shaped base that succeeded the VS1, featuring a head front access door, thumb plate tension release, pillar stitch adjustment and a low mounted bobbin winder.